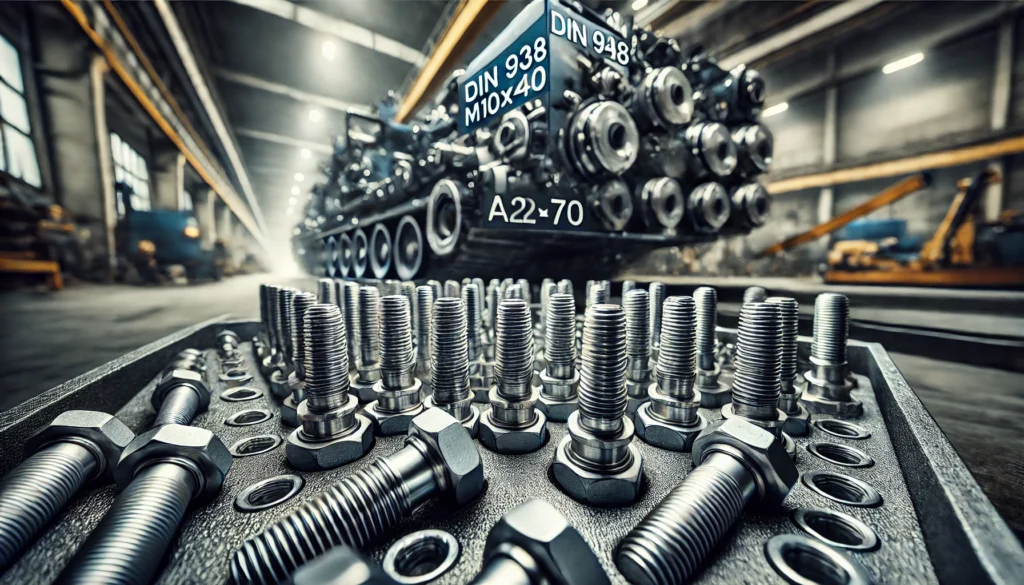

The DIN 938 – M10x40 – A2-70 – L2A Elesa is a high-performance double-ended stud used in various industries for secure and reliable fastening. In this guide, we’ll break down its key specifications, manufacturing process, applications, advantages, and maintenance tips.

Understanding these elements will allow engineers, technicians, and buyers to make informed decisions about this essential fastener.

What is DIN 938?

The term DIN 938 refers to the standard in the German Industrial Norm (DIN) system that governs the specifications for double-ended studs. A double-ended stud, such as the DIN 938 – M10x40 – A2-70 – L2A Elesa, is a versatile fastener used for connecting two components. These studs are threaded on both ends and serve as a bridge between parts requiring secure fastening.

Key Specifications of the M10x40 Stud

The M10x40 indicates specific dimensions:

- M10 refers to the 10 mm diameter of the stud.

- 40 indicates the length of the stud, which is 40 mm.

Material Type – A2-70 Stainless Steel

The A2-70 classification of stainless steel refers to a specific grade known for its excellent corrosion resistance and good mechanical strength. A2-70 stainless steel is widely used in outdoor, marine, and industrial environments due to its ability to withstand rust and oxidation.

Surface Finish – L2A

The L2A surface finish is a treatment applied to the stud, making it more resistant to wear, reducing friction, and improving its overall durability. This finish helps the fastener perform better in harsh conditions, providing an extended service life.

Detailed Specifications of the DIN 938 – M10x40 – A2-70 – L2A Elesa

Let’s take a deeper dive into the precise specifications of the DIN 938 – M10x40 – A2-70 – L2A Elesa stud.

Thread Dimensions

- The stud has a M10 thread size, meaning the stud is designed with a 10 mm diameter and a specific pitch that ensures it securely holds in threaded holes.

Length and Thread Length

- The 40 mm length provides ample coverage for fastening components together, with threads extending from both ends. This design allows for efficient attachment to nuts or tapped holes.

| Specification | Detail |

| Diameter (M10) | 10 mm |

| Length (M10x40) | 40 mm |

| Material | A2 Stainless Steel |

| Surface Finish | L2A |

Material Properties of A2-70 Stainless Steel

The A2-70 stainless steel used in this stud has a chemical composition designed to resist corrosion, especially in environments where exposure to moisture, chemicals, and extreme temperatures occurs. It is also characterized by a tensile strength of 700 MPa (megapascals), making it a robust material for heavy-duty applications.

Surface Finish and Durability

The L2A surface finish provides a smoother finish to the stud, improving its resistance to abrasion and minimizing friction during use.

This treatment is particularly beneficial in industrial applications where the fastener is subjected to frequent motion or stress.

Manufacturing Process of DIN 938 – M10x40 – A2-70 – L2A Elesa

Material Selection

The A2-70 stainless steel is selected for its balance between corrosion resistance and mechanical strength. Manufacturers choose this material for fasteners in various sectors that require dependable, long-lasting parts.

Thread Rolling and Surface Treatment

Once the raw material is chosen, the studs undergo thread rolling, which ensures high precision in the thread pattern. After threading, the studs receive the L2A surface treatment, which enhances their durability and resistance to wear.

Quality Control

Every DIN 938 – M10x40 – A2-70 – L2A Elesa stud undergoes strict quality control to ensure it meets industry standards and performs reliably in different applications. Quality checks include dimensional accuracy, material testing, and corrosion resistance.

Applications of DIN 938 – M10x40 – A2-70 – L2A Elesa

The DIN 938 – M10x40 – A2-70 – L2A Elesa stud is used in various industries where reliability and strength are paramount.

Automotive Industry

In the automotive sector, these studs are used in engine blocks, suspension systems, and chassis assemblies. Their tensile strength and corrosion resistance ensure they withstand harsh operating conditions.

Construction Sector

In construction, these studs are ideal for structural steel connections and heavy-duty machinery assemblies. The DIN 938 – M10x40 – A2-70 – L2A Elesa is trusted for providing the strength needed for secure structural integrity.

Industrial Machinery

Heavy equipment and industrial machines rely on these fasteners for their durability and performance under stress. The M10x40 studs are used to fasten critical components in machines such as conveyors and lifting systems.

Marine Applications

Thanks to its A2-70 stainless steel material, this fastener is perfect for marine applications, where resistance to saltwater corrosion is a crucial factor. The L2A finish also enhances its performance in salty and humid environments.

Advantages of DIN 938 – M10x40 – A2-70 – L2A Elesa

High Tensile Strength

The A2-70 material ensures the stud can withstand high tension without breaking or deforming. This makes it an excellent choice for critical fastening applications.

Corrosion Resistance

Due to the use of A2 stainless steel, the stud is highly resistant to corrosion, making it suitable for use in environments exposed to moisture, chemicals, or extreme weather.

Versatility

The DIN 938 – M10x40 – A2-70 – L2A Elesa stud can be used across different industries, including automotive, construction, marine, and industrial machinery, providing a versatile solution to many fastening needs.

Cost-Effectiveness

While these studs offer high durability and performance, they are available at a competitive price, offering long-term value by reducing maintenance costs and enhancing reliability.

Installation Guidelines for DIN 938 – M10x40 – A2-70 – L2A Elesa

Preparing the Components

Before installation, ensure that the parts to be fastened are clean and free from debris. This will help ensure a secure connection and avoid damaging the threads.

Torque Specifications

Proper torque is crucial to achieving optimal performance. Always follow manufacturer guidelines for torque specifications to prevent over-tightening or under-tightening.

Lubrication

Using the right lubricant can improve the installation process, making it easier to thread the stud into place and reducing friction.

Common Mistakes to Avoid

- Over-tightening: Applying too much force can damage the threads.

- Incorrect torque: Using incorrect torque values may result in a loose or weak connection.

- Ignoring lubrication: Lack of lubrication can increase friction and cause wear over time.

Maintenance and Longevity of DIN 938 – M10x40 – A2-70 – L2A Elesa

Regular Inspections

Inspect the studs periodically for signs of wear or corrosion, especially if used in harsh environments. Early detection of issues can prevent failures.

Cleaning Procedures

Cleaning the studs helps remove dirt and corrosion. Use a soft cloth and mild cleaner to avoid damaging the surface finish.

Lubrication Practices

Lubricating the threads during installation or regular maintenance helps reduce friction and wear, extending the stud’s lifespan.

Identifying Wear and Tear

Look out for thread deformation, rust, or signs of loosening during inspections. If the stud is worn out, it’s important to replace it promptly to maintain safety and functionality.

FAQs:

Can the DIN 938 – M10x40 – A2-70 – L2A Elesa be used in high-temperature environments?

Yes, the A2-70 stainless steel is heat-resistant up to a certain point, but it is not suitable for extreme high-temperature applications. For those, a higher-grade material like A4 stainless steel may be needed.

What is the difference between A2-70 and A4-80 stainless steel?

A4-80 stainless steel offers higher corrosion resistance compared to A2-70, especially in marine environments. A2-70 is more common for general industrial applications.

How do I determine the correct torque for installing DIN 938 studs?

The correct torque specification depends on the material and thread size. Refer to the manufacturer’s guidelines or industry standards for accurate torque values.

Is the L2A surface finish suitable for all types of environments?

The L2A surface finish provides excellent wear resistance and is ideal for most industrial and marine environments. However, for extremely harsh conditions, a more robust coating may be necessary.

Can DIN 938 – M10x40 – A2-70 – L2A Elesa be used in food processing equipment?

While A2 stainless steel offers corrosion resistance, it’s recommended to use food-grade stainless steel (A4) in food processing environments to ensure compliance with hygiene standards.

Are DIN 938 studs reusable?

Yes, DIN 938 studs can be reused, provided they are inspected for damage, corrosion, or thread wear before reinstallation.

What tools are required to install DIN 938 – M10x40 – A2-70 – L2A Elesa studs?

Standard hand tools like wrenches and torque wrenches are sufficient, but ensure they match the stud size and follow proper torque specifications.

How do I know if I have the genuine DIN 938 – M10x40 – A2-70 – L2A Elesa stud?

Check for certification marks or purchase directly from reputable suppliers to ensure the product meets the DIN standard and material specifications.

Can DIN 938 – M10x40 – A2-70 – L2A Elesa studs be used in high-pressure applications?

While they provide great tensile strength, for extremely high-pressure applications, it’s essential to assess the specific requirements and use studs rated for such environments.

conclusion:

the DIN 938 – M10x40 – A2-70 – L2A Elesa stud offers strength, durability, and corrosion resistance, making it an essential fastener across multiple industries. Its high-quality materials and surface finish ensure reliable performance in harsh environments.

Proper installation and maintenance can extend its lifespan, providing long-term value. This stud is a trusted solution for securing critical components in automotive, construction, and industrial applications.

recommend article:

Understanding Italian Men – A Comprehensive Guide!

The Ultimate Wordle Tom’s Guide – Mastering The Daily Puzzle!

My Olsd – A Comprehensive Guide To Embracing Old Age!

The Ultimate Guide To Jcss44347 – A Comprehensive Explanation!